MOBILE SYSTEM

PressureWave+™

PressureWave+™ cleans safely and efficiently during operations

For over 20 years, customers around the world have relied on the mobile PressureWave+™ process to clean boilers safely and efficiently during operation. This proven, patented, proprietary technology licensed through Bang&Clean uses targeted and controlled gas explosions to generate pressure waves that efficiently remove debris in industrial plants. The mobile PressureWave+™ cleaning system is suitable for use in boilers, steam boilers, silos, hoppers, and other exposed parts of energy production systems. Examples include Energy from Waste (EfW) plants, biomass, Heat Recovery Steam Generation (HRSG), paper and cement plants.

1

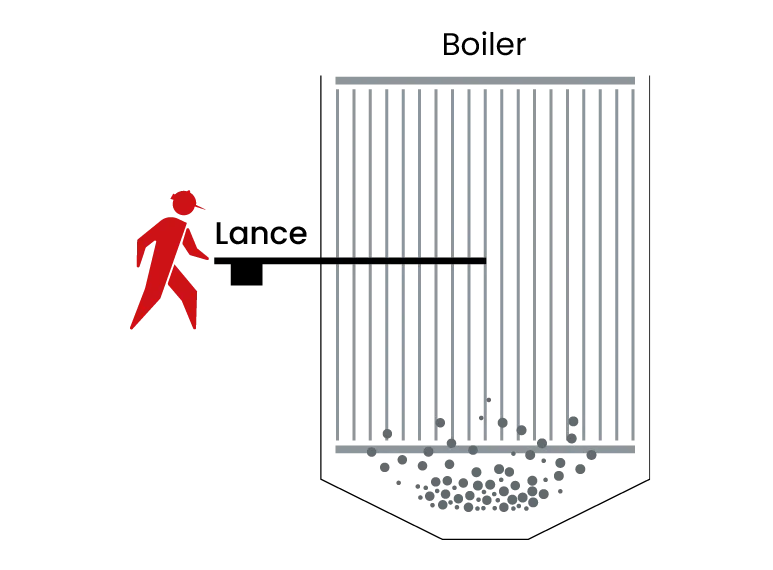

Two gases are fed and controlled separately to the lance head. Through a boiler opening (door, view port, nozzle), the water-cooled lance with a pre-assembled special sleeve is placed near the surface to be cleaned.

2

The sleeve is inflated with the ignitable gas mixture and deliberately detonated.

3

Two pressure wave loosens ash and slag deposits on walls, tube bundles or filter systems deep into the bundles - these fall into the hopper and can be extracted via the discharge system.

Here's how it works

After initial evaluation, our service specialists guide a water-cooled lance with a pre-assembled special bag through the boiler door or through an inspection hatch close to the surface that is to be cleaned. There, the special bag is blown up with a combustible gas mixture and is exploded. The resulting pressure wave dissolves ash and slag deposits on walls, pipe bundles and filter systems deep into the interior of the system. The loosened debris falls into the hopper and exits via the discharge system. The PressureWave+™ process is safe for both people and equipment, and operates at temperatures up to 1200°C.

Safe for people and equipment

The patented and certified pressure wave cleaning processes are safe for people and boiler structure. Continuously developed according to the latest scientific findings, they are suitable for practically all energy-producing industrial plants: from waste and hazardous waste to energy plants to biomass and coal power plants to the paper, gas, and cement industries. Moreover, pressure wave cleaning is just as successful in all other industrial plants with inert material flows.

Before and after

PressureWave+™ at a glance

- Mobile cleaning system using pressure waves

- Ready to use in no time

- Targeted cleaning during operation (95% during operation)

- Extended operating time

- Cleaning frequency depends on level of fouling

- Maximum safety for people and equipment